Why the Chevrolet Colorado ZR2 Is Off-Road Capable but Doesn't Beat You Up

As a factory option, a typical off-road suspension usually means your spine is going to be hammered much more than if you were driving a pickup truck’s standard suspension. And when it comes to purpose-built off-road icons that may be more forgiving, they tend to be exceptional at one type of off-roading but not as good at others and/or pavement driving. So how does the Chevrolet Colorado ZR2 ride better than the typical off-road suspension option, perform better off-road as well and not make as many sacrifices as other trucks of its type?

Related: Off-Road Comparison: Can the Gladiator Rubicon Dethrone the Colorado ZR2?

The short answer is the ZR2’s shock absorbers, which are highly sophisticated yet delightfully simple — and low tech only if your definition of tech requires electricity, because unlike any other suspensions with the versatility of the ZR2’s, these shock absorbers aren’t computer controlled or even remotely adjustable. Below I’ll explain how they work and why they’re so revolutionary, especially in an off-road vehicle.

To back up a second, understand that when I refer to typical optional off-road suspensions, I’m talking about your garden-variety, decades-old off-road options that currently have names like Ford’s FX4 and Chevrolet’s own Z71, which has been available on the Colorado since before the ZR2 made its debut as the brand’s ultimate off-roader for 2017. If the regular Z71 off-road suspension option was firm, certainly the ultimate off-road suspension would put us in traction, right? Wrong.

Not only does it ride better on the mean streets of the Midwest and in high-speed desert-running scenarios, as we found out in our recent head-to-head testing of the 2019 Chevrolet Colorado ZR2 diesel Bison and 2020 Jeep Gladiator Rubicon, but the ZR2 does a very good job of climbing rocks as well. Notably, when you focus on suspensions alone, even the iconic specialists aren’t as well rounded as the ZR2: The Gladiator, like the Wrangler Rubicon on which it’s based, was a superior rock crawler but it bottomed out too easily in the dunes. The Ford Raptor, a brilliant sand-runner, isn’t as adept at rock crawling and has traditionally been very wallowy on pavement (the 2019 has added electronic adaptive damping to its bypass shocks and may be a different experience). On pavement, the ZR2 Bison was still a truck but was nicely controlled with handling far superior to the Gladiator’s.

‘We Were Going to Do Both’

I spoke with two of the engineers behind the Colorado ZR2 to find out what they set out to accomplish and how the revolutionary shock absorbers helped them get there. Asked about the traditional off-road suspensions and their well-earned reputations as rough riders, Brad Schreiber, now GM’s performance variant manager for mid-size trucks, explained that the mass-market approach had always been a compromise that couldn’t sacrifice too much capability in exchange for one off-road calling card like the Raptor and Wrangler have.

“Before those [models] came into their own and were recognized as sort of the bookends of the spectrum, it was really left to the [manufacturer] to dictate what the vehicle was going to be used for and bias that,” Schreiber said. “It was basically splitting down the middle — running across open fields, running a two-track. Sort of that general off-road-use case, and you’ve got to be able to get payload and everything else through those types of scenarios and have the long-term durability, etc. And that obviously backed up toward the higher spring rates, the higher damper characteristics.”

When Chevrolet set out to build the ZR2, it didn’t want the truck to be split down the middle like a traditional off-road suspension, or for it to be a one-trick pony, either.

“When we all sat down and started scoping out what the ZR2 should be, I remember one of the early conversations with senior leadership,” said Darren Bohne, chief performance engineer for ZR2. “I likened it to saying, ‘I’m going to build you a racecar.’ Well, to one person that’s a quarter-mile drag car. To another person that’s a Z28 road-racing machine. So when we said we were going to build an off-road truck, we were very specific in the fact that this truck was going to be desert racing capable — you know, Chad Hall racing out there running the Baja 1,000 — but we were also going to the Rubicon Trail. You don’t see Raptors running the Rubicon and rarely do you see Jeeps running the Baja. We set out with a vision that we were going to do both. And then we took that vision to Multimatic and shared a technology that this space has never seen.”

Multimatic, the company that developed Dynamic Suspensions Spool Valve shock absorbers for use in professional racing, began supplying the 2014 Chevrolet Camaro Z28 as the first volume production car with the technology. Chevy says it approached the company to see if the technology was the key for an off-road truck with fewer compromises. Clearly, it was.

Related: Find a Chevrolet Colorado ZR2 for Sale Near You

How Shock Absorbers Work

If you’re unfamiliar with how shock absorbers work, don’t run away just yet. No one should blame you for imagining big springs inside, but that’s not the operative part. (Large springs are another part of the suspension that support the vehicle and absorb a good deal of the shocks themselves; shock absorbers are probably better termed “dampers,” which is what the British and many engineers and gearheads call them anyway.) There are a few small springs inside shock absorbers, but the way they work is through hydraulics. They’re filled with oil, and a shaft with a piston head on the end passes through a central tube like a plunger through a medical syringe. Instead of the oil squirting out when the damper is compressed, imagine that the syringe is inside a second, larger tube, and the oil simply backs up around the syringe into the larger tube.

If you’ve ever used a syringe (we’re not asking any questions), you might have noticed that if you try to squeeze the plunger faster, it resists as the liquid is trying to squeeze out of the narrow tip. The same principle is what resists shocks in all shock absorbers. There are holes, called orifices, at different ends of the damper, sometimes in the piston head itself, that restrict the flow of oil. Small compressions and rebounds allow the oil to flow freely, but if there’s a fast shock, like a bump, the damper will resist more forcefully. The larger the orifices, or the more of them, the freer the oil flow and the lower the damper’s rate, meaning the softer it is. (Traditional adaptive shock absorbers that can change from soft to firm do so with electric valves that vary the size of the orifices within microseconds under computer control, but we’re talking about passive dampers here; I just figured I’d throw that in.)

The Problem, and Multimatic’s Solution

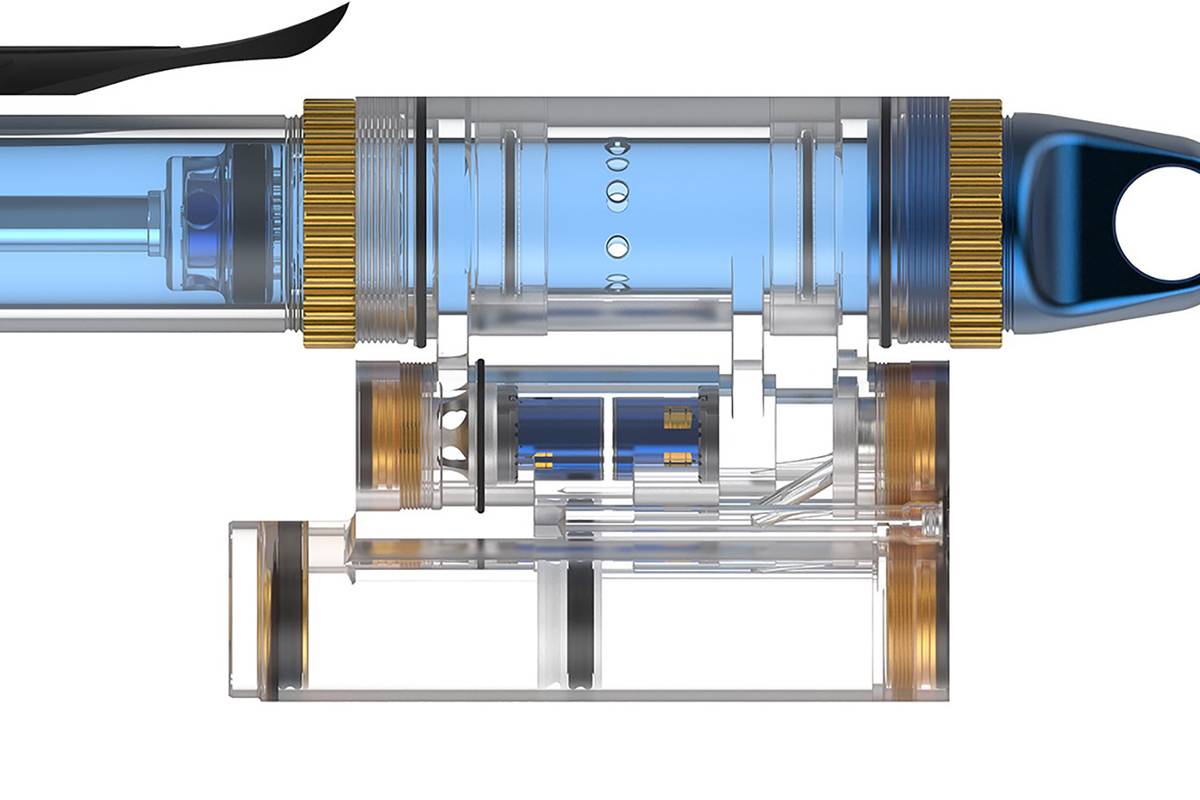

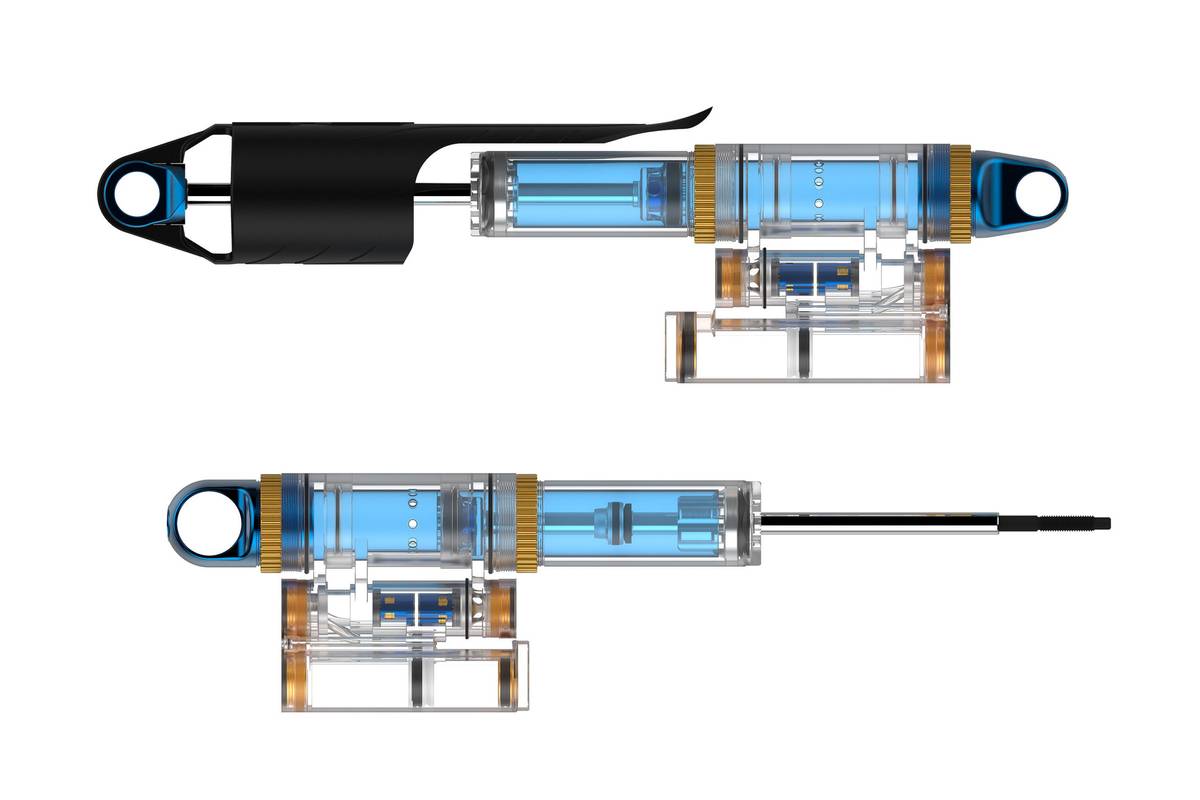

One of the limitations of this conventional design is that of the passive valves that control the rate and direction of oil flow through the orifices, which are made up of stacked flexible metal discs. Called shim valves or deflected discs, they can deflect only so much, so these valves are limited in their range and how they respond to pressure. In their place, Multimatic uses a cylinder that gearheads might mistake for a valve lifter with holes in the side. In the photo of the transparent ZR2 damper below, two of the spool valves are identifiable as the dark-blue, top-hat-shaped pieces in the middle of the three tubes. Each spool valve has a gold-colored inner shuttle cylinder backed by a coil spring that slides within the top-hat cylinder you see in the photo. When the oil is pressurized, the shuttle moves inward, exposing the holes in the walls of the outer cylinder. The amount of pressure determines the size and shape of the valve’s openings. Engineers can vary the damping rate by adjusting the valve’s spring rate and the shapes of these windows.

“You’ve got these port windows that can be absolutely any shape your imagination can conjure up to flow through it, and every shape is going to yield a different force velocity curve, and what we can do with that technology is we can create a curve that is otherwise unobtainable with the traditional deflected disk system,” Schreiber said.

Position Sensitivity for the Off-Road Win

But it’s not the spool valves alone that work the magic in the ZR2, because other vehicles have had them as well, including the Z28 and the latest Camaro ZL1 1LE. It’s the fact that the ZR2’s DSSV dampers are position sensitive, which means they’re sort of like dual-rate springs. They’re relatively compliant for roughly two-thirds of their compression and then firm up considerably for the final third — which is why I was able to bound over dunes at much higher speeds in the ZR2 Bison than I was in the Gladiator.

“Because we have these different zones and they have such discrete tuning capability within them, we have the best of both worlds, and they seamlessly flow in and out of each other,” Schreiber said. “You never feel some sort of step transition from one to the next.”

Each damper has three spool valves total. The valves mentioned above in the center tube are actually the primary compression and rebound valves. When the piston in the large main tube comes down, it forces the oil out of the holes visible in the wall of the inner, light-blue tube into the containing tube and then it flows through ports into the neighboring middle tube and through the compression spool valve before returning through another port to the top of the larger tube. Upon rebound, the oil reverses direction and goes through the rebound valve.

The third spool valve is incorporated into the head of the piston. It comes into play only when the piston passes those holes in the main tube, trapping the oil in the final third of its travel. This firmer-rate valve is what absorbs the energy of a full compression. What about the third tube at the bottom? That’s just a reservoir for the oil and pressurized nitrogen gas, which is standard in modern shock absorbers to prevent oil foaming. In the photo, you can see the diaphragm that separates the two.

Asked why the shock is shaped as it is with three tubes, Schreiber said, “One of the big drivers was purely packaging. We had a limited space, as any vehicle does, to fit this damper system into. We had to fit additional components into it. If we just wanted to create an on-road truck that had spool valves for the jounce and rebound, we could have had a more compact unit, but because we were also piggybacking the position-sensitive element — basically having different valving systems to take over when you get to the extremes of travel — that’s what forced the additional piggyback tube that you see on there today. Realistically you could configure those in a whole host of setups.”

We’ve already touched on the main advantages of the DSSV design, but it doesn’t end there. They’re also excellent at casting off the heat generated by demanding off-road use. “They’ve got aluminum bodies, which are extremely efficient at dissipating heat,” Schreiber said. “You’ve got these exterior chambers where you’re flowing all of your oils, so those are basically acting as mini radiators.”

But heat seems less of a concern here than with traditional damper designs. “The way the hydraulic system is designed, they’re basically immune to turbulent flow, which is something that happens when you’ve got high speeds, quick directional changes, with heat compounding,” he said. “These [dampers] don’t care. The harder you work them, the more they perform. … Instead of trying to get a perfect linear flow across a stack of discs and having them deform equally on all sides, we’re forcing oil through an orifice. That orifice doesn’t care how the velocity and flow patterns behave. It’s dictated by physics.”

It’s clear that GM’s engineers are as enthusiastic about the damper technology as we are from experiencing it. The company is characteristically tight-lipped about future products, but naturally, we’d like to see more from the power duo of GM and Multimatic. For them not to do so would be something like malpractice.

Cars.com’s Editorial department is your source for automotive news and reviews. In line with Cars.com’s long-standing ethics policy, editors and reviewers don’t accept gifts or free trips from automakers. The Editorial department is independent of Cars.com’s advertising, sales and sponsored content departments.

Former Executive Editor Joe Wiesenfelder, a Cars.com launch veteran, led the car evaluation effort. He owns a 1984 Mercedes 300D and a 2002 Mazda Miata SE.

Featured stories