Pickup Trucks 101: What You Need to Know About Traction

Have you ever tried to accelerate quickly to merge onto a high-speed highway in bad weather and been stuck spinning one wheel? Open differentials are important when making turns as they allow for the outside tire to move faster than the inside tire; unfortunately, they also allow all the power to go to the wheel with the least amount of traction. In most driving conditions this is fine, but when driving in inclement weather or on rough or muddy terrain, the vehicle can get stuck spinning one tire on a slick spot while the other three have great traction. Hauling or towing a heavy load can make driving in these conditions with an open differential even more difficult.

To combat this, many manufacturers offer some form of traction aid. These range from applying the brakes on the spinning wheel(s) by using the antilock braking system to locking the differential so that both wheels spin at the same speed regardless of what surface the tires are on. Many systems offer a combination such as the Toyota Tacoma, which has active traction control and an electronic locking rear differential.

Antilock Braking Systems

Many manufacturers offer ABS traction control standard on their pickups and SUVs. Some manufacturers go beyond basic traction control with an off-road version. These types of systems can be found on Toyotas, Nissans, Jeeps, Ford, GMs, Rams and many others. Vehicles with ABS have sensors on each wheel to determine if a wheel is locked when it should be spinning and if the ABS needs to be activated for that wheel. These same sensors and antilock brake systems are used to brake a wheel that is spinning significantly faster than the opposite wheel on the same axle. These systems are inexpensive since they use hardware that is already in place. The downsides to these systems are that they can produce loud grinding sounds, overheat if used too much, and cause extra wear and tear on the brake system. Many can be turned on and off by pushing a button. They are also sensitive to throttle and brake inputs, and have a bit of a learning curve, but once mastered ABS traction can be invaluable.

Limited-Slip Differentials

There are two main types of limited-slip differentials: gear driven and clutch driven. Gear-driven differentials, often referred to as Torsen differentials, use worm screws and worm gears to control the amount of torque being sent to each axle. There is no banging or slamming found in gear-driven limited-slip differentials because they are always engaged. They are also strong and don’t require special additives to the gear oil. Gear-driven differentials work on a torque multiplying system. If a differential has a bias ratio of 3:1 it will multiply the torque on the low traction tire by 3 and send that much torque to the high-traction tire. If the wheel with less traction has 40 pounds-feet of torque resistance, then the other side would have 120 pounds-feet of torque transferred to it. The downside to this system is when one tire has no traction the differential can’t send torque to the tire with traction because any number times zero equals zero. In many situations, applying the brakes and throttle at the same time will allow enough torque to transfer to the tire with traction to get the vehicle moving again. These types of differentials are commonly used in the rear differentials of trucks and SUVs, the center differentials of all-wheel-drive vehicles and even sometimes in the front differential, such as the desert-running Ford F-150 Raptor.

Clutch-driven differentials work much like the clutch in a manual transmission, but they use a series of clutch plates to add torque to the wheel with traction. Often they are sensitive to the speed difference between the wheels, meaning the faster one wheel spins in comparison to the other the more torque gets sent to the wheel with traction. These differentials can transfer torque to the wheel with traction even when the opposite wheel has no traction. The downside to clutch-driven differentials is that they wear out with time and need to be rebuilt. They also require friction additives in the gear oil to ensure that they work effectively.

Locking Differentials

There are many types of locking differentials, but they all work by forcing both wheels to spin at the same speed, effectively creating a 50/50 torque split between the wheels. Manufacturers offer two main types of locking differentials: electronic locking and auto locking.

Electronic-locking differentials, or e-lockers, operate by using an electromagnet or a solenoid to engage the locker. These are offered in many Toyota, Ford, Ram and Nissan trucks and SUVs. They are predictable; the driver chooses when to engage or disengage the mechanism, but most can only be engaged when the vehicle is in 4-Low and not while moving. This can cause problems in normal driving conditions where you don’t want the differential locked full time, but hit a slick spot and the vehicle is stuck or significantly slowed from spinning one wheel. The Toyota Tacoma and 4Runner; Nissan Frontier; Ford Raptor, F-150, F-250 and F-350 have e-lockers. The venerable Ram 2500 Power Wagon has electronic locking front and rear differentials and a gear-driven limited-slip in the rear.

Auto-locking differentials are activated when one wheel spins about 100 rpm faster than the other wheel on the same axle. The difference in speed causes a mechanism to activate and lock the axles together. These can engage with a bang and can even cause damage to the axles or differential if the traction difference between the two wheels is high. They work well in most conditions. GM’s Eaton G80 used in many of its trucks and SUVs is an example of an auto-locking differential. Auto lockers can engage even if one wheel has zero traction or is lifted off the ground. The downside is that the driver doesn’t get to choose when to engage or disengage the locker.

Other types of locking or locked differentials include air, hydraulic, cable, ratcheting and spools. There are even some complicated electric over vacuum over hydraulic systems like the one in the Mercedes-Benz G-Class. Most of these are available as aftermarket options and they all work differently. Air, hydraulic and cable differentials are similar to e-lockers in that drivers can lock and unlock the differential when they want. Ratcheting differentials are always engaged and allow the outside wheel to spin faster than the inside wheel, but neither can spin slower than the ring gear in the differential. Spools eliminate the differential, so they have a 50/50 torque split all the time.

Which Differential Is Best for You?

Each type of traction device has benefits and disadvantages. Each performs differently in different situations, and there isn’t a single type that is best for everyone. Driving style, preferred activities, climate and location are important considerations when choosing a traction device. Following is a short description of the types of traction devices generally used in a particular situation. However, what works best for one person may not work for another person in the same situation. Those who rock crawl equip their vehicles with selectable lockers such as an e-locker or an air locker because they offer the most control and predictability in low-traction situations.

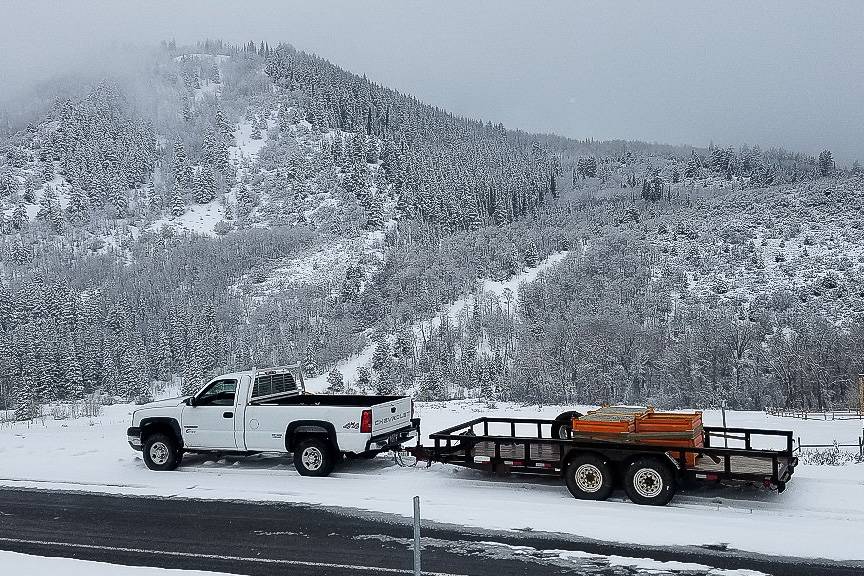

When driving in muddy, snowy or icy conditions, a limited slip or auto locker is often easier to manage because they only engage when slip is detected. When hauling a heavy load, or pulling a trailer, a gear-driven differential is a good choice because the increased weight on the rear axle can create a greater traction difference between the two wheels. In this situation, clutch-style devices will wear more quickly than if they were lightly loaded, and auto-locking devices will engage harder, also causing greater wear. Spools are only used in special applications since they are difficult to drive on the street in any condition.

Even more important than which traction device or system you have is knowing what you have and how to use it. Locking and limited-slip differentials behave differently. A gear-driven limited slip is different than a clutch-driven limited slip, and an auto locker is different than a selectable locker. The ABS traction aids also have their own “sweet spots” in which they work best. Simply knowing what your pickup has and how to use it in a given situation will allow the truck to continue on its way despite bad weather or rough terrain.

Cars.com’s Editorial department is your source for automotive news and reviews. In line with Cars.com’s long-standing ethics policy, editors and reviewers don’t accept gifts or free trips from automakers. The Editorial department is independent of Cars.com’s advertising, sales and sponsored content departments.

Featured stories